Making the new paper garden (part 1)

“To re-inhabit the places in which we live is not to raze the smokestacks and freeways that we might find there but to fit them back into the larger unfolding of land and cosmos.”

— Freya Mathews

It’s Thursday morning and the Google Teams window opens, I am a few minutes late and the discussion is already in full flight. People are speaking in short sentences . I am all ears as our fast flowing conversation is full of much needed information. This is the design team meeting for our new Paper Garden build and words like ‘truss retention, access process and CDM regs and responsibility’ fill the virtual space between us. We have been meeting every two weeks for months; in fact since November last year and by now we are a well-oiled machine.

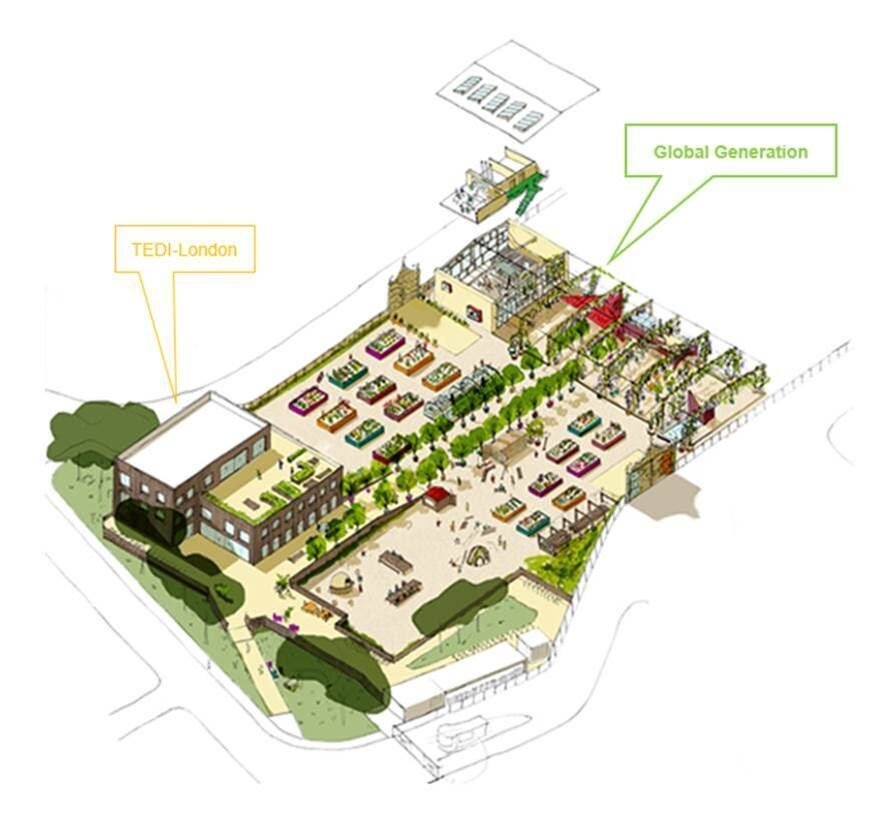

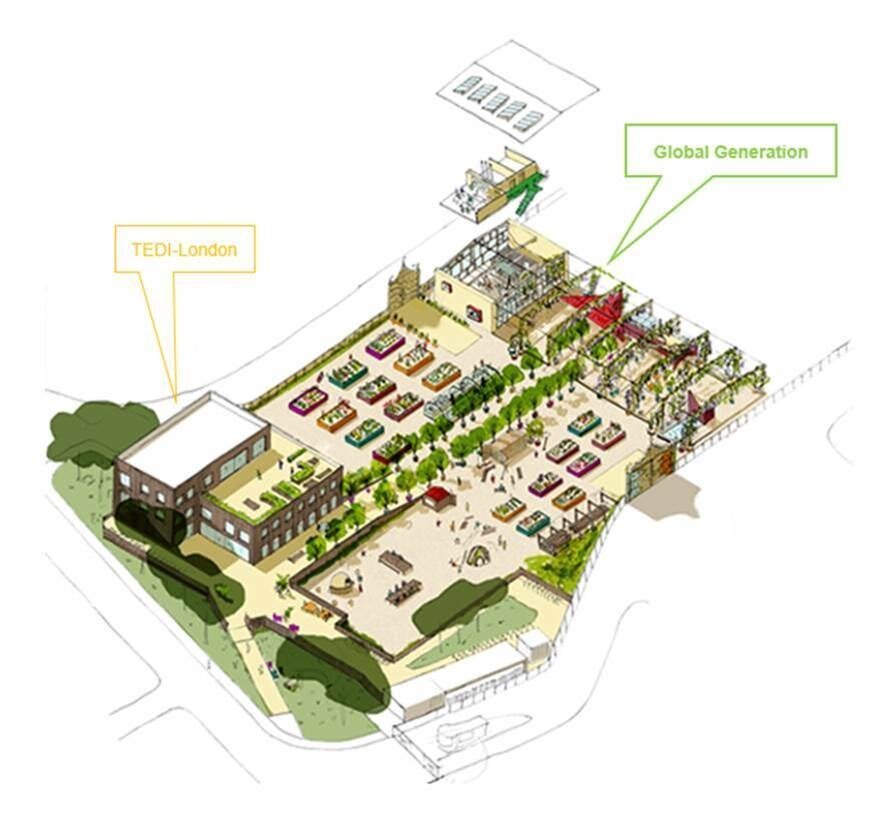

This is a team made up of many of the parts we need for our not so ordinary build; our two architects from Jan Kattein Architects; Jan and his colleague Heloise Dessaisement, Lewis Hosier the Project Manager from Aecom , Charlie Scott the structural engineer from Watermans, Toby Croft the mechanical engineer from Sweco, Hugh Sowerby Planning Consultant from DP9 along with David Walters and Phil Tait who are from British Land the project sponsors and land owners. The not so ordinary part of the build is not that it is being done largely on a pro-bono basis by the consultants and construction contractors, Global Generation has a history of creating gardens that way. The extraordinary aspect of this is the approach; we are doing a few things at scale that as far as we are aware have never happened in London before.

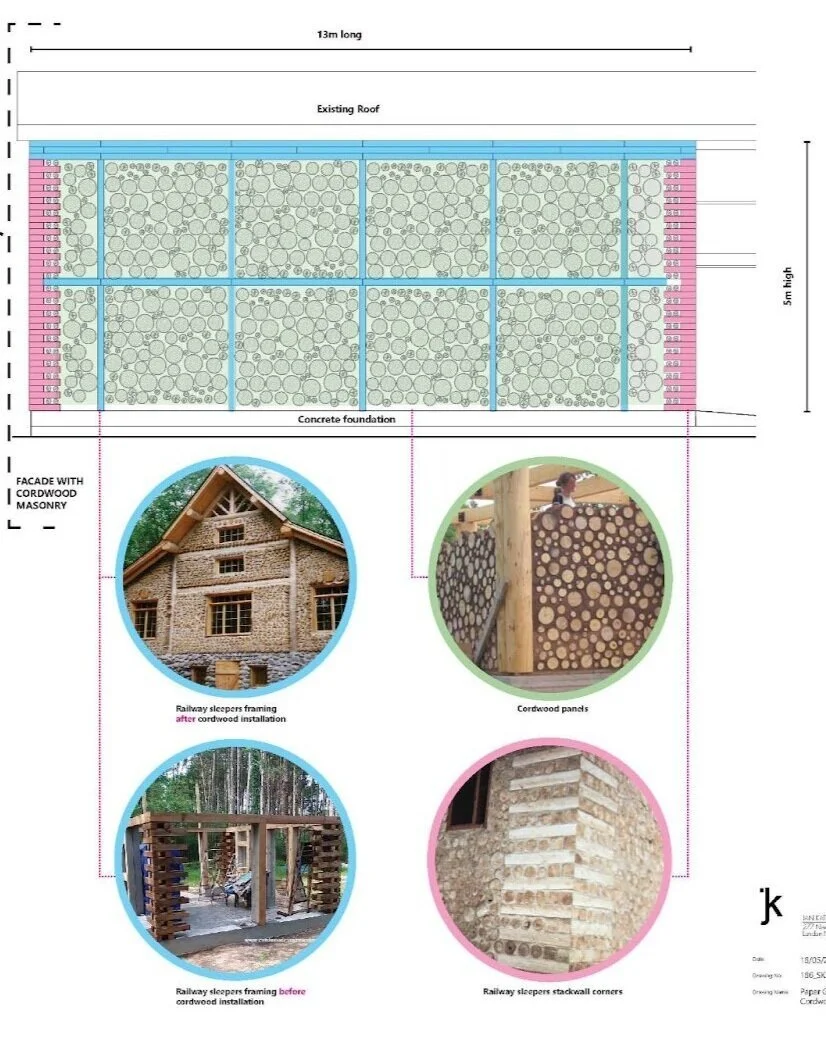

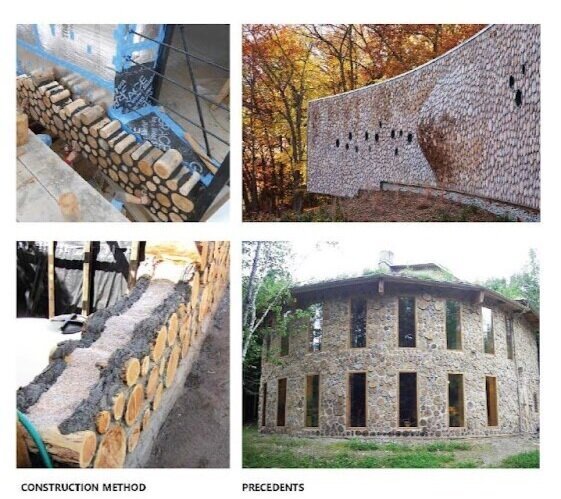

We are planning the build of a 300 square metre Education Shed, inside an enormous stripped out shed that was once used to store paper for the Daily Mail. Not much will remain of the existing shed, a few sections of roof and the trusses, enough to grow plants up and sling a sky bridge across, one of the many things salvaged, this time from the Daily Mail Printworks. Inside will be a new building with a second story mezzanine floor, a kind of giant parquet floor made of 160 up-cycled doors. Two of the facades will be constructed out of cordwood. Thanks to Danny Murphy from the Corporation of London Conservation team, we will be collecting cordwood from the well-seasoned wood piles across Hampstead Heath. As with all of our gardens the New Paper Garden will be a garden of a thousand hands with community building activities at its heart. Cordwood construction was chosen not only for its environmental credentials but also because it lends itself to volunteer engagement. Yes Make, an organisation skilled in the art of combining wood, community and sustainability who have been working with GG, will lead on the construction of the cordwood walls.

A shorthand way of describing Global Generation’s work is ‘bringing out the life beneath the concrete’. A natural first step in our design process was engaging Global Generation’s, young Generators (Eco ambassadors). They are the ones that have inspired our efforts to turn a hard core industrial landscape into a sanctuary for all aspects of the natural world including humans. The Generators had a lot to say about how they wanted the new Paper Garden to be:

I want the garden to make people feel it is their home … after COVID I want it to help people to feel tranquil and mesmerised by the beauty of nature and all the creative things we can do with natural materials … when you step inside I want you to feel that the world doesn’t exist, only the here and now

I have learned to ride the many unknowns in what has turned into the most ambitious community build project Global Generation has ever embarked upon. All of our other builds were for structures under 30 metre square which makes things a whole lot easier in terms of building control regulations; appropriate fire protection being the biggest issue with so much wood. Thankfully we are being well guided by Andrew Cullen our Building Control Manager from BRCS who is also on our team. There have been moments, especially in the small hours of the night, when I have wobbled; worrying about the complexities of what we are doing. Whilst exciting, I worried if I would be exposing the charity to financial risk, or if the demands of the project would distract us from our work with children and young people. Jan explained to me that we need to be ambitious in sustainability terms, not only for our own environmental education work but because many in the industry are turning this way and wondering how they can creatively turn the tide on the huge amounts of waste that are coming off construction sites. Jan’s foresight has proved to be right, as different people have stepped forward to help, first the consultants and then the real deal breaker was when Jim Watts from Wates suggested Bethany Lilley, a site manager come and work with us and they would support her, financially and practically. Wates, along with other construction contractors, Keltbray and Gouldris, who have helped behind the scenes are now figuring out what their commitment might be in terms of providing the many trades required for doing the actual build.

The team are all passionate about the overriding circular economy ethos; building from what we can find, not what we can buy. This has brought forth real ingenuity and teamwork in the design process. Whilst the scale of what we need is a little daunting, it has been exciting ticking off our wish list of materials. Along with the cordwood, other significant donations have come our way; a disused metal staircase from a local fire station, 300 untreated hardwood sleepers for the corners of the cordwood construction and new garden beds came from Network rail, along with all of the double and triple glazed windows that will be mosaiced together on the two long facades. The windows are from Nordan’s store of surplus windows that were the wrong size for buildings across the country, they are seldom upcycled and like many things it is easier to send them to landfill.

As I write this I get a phone call from David Walters of British Land, he sounds excited “I think I have got good news for you” he says, “the enabling works will begin next week”. We had initially received an eye watering figure that would have completely blown our budget for the enabling works, in other words stripping down the shed ready for our build. This time it is Keltbray who have come through offering the services of their team and their supply chain at a hugely preferential, partly pro-bono rate.

There’s no doubt that finding a good way into the future for ourselves and the planet is a project that will take all of us; along with significant hurdles there will be many breakthroughs and many stories to tell. Already I can see that our New Paper Garden will have stories to tell about the many places the materials have come from and the many people that have found new ways to work together. It gives me heart that there is a currency of good will which brings meaning and weight to a phrase I often use; ‘we are travelling hopefully’.

It’s a beautifully golden afternoon in late October, and I am sitting in Somers Town on a table outside the pub, admiring the seven foot sunflowers that are growing opposite the medical centre.